No products in the cart.

Silicone products are popular due to their versatility and durability, and they can be customized for a wide range of applications. However, the cost of creating customized silicone products can vary depending on the complexity of the design and the type of mold required. Here are some key factors to consider when evaluating the molds cost of silicone products.

Complexity

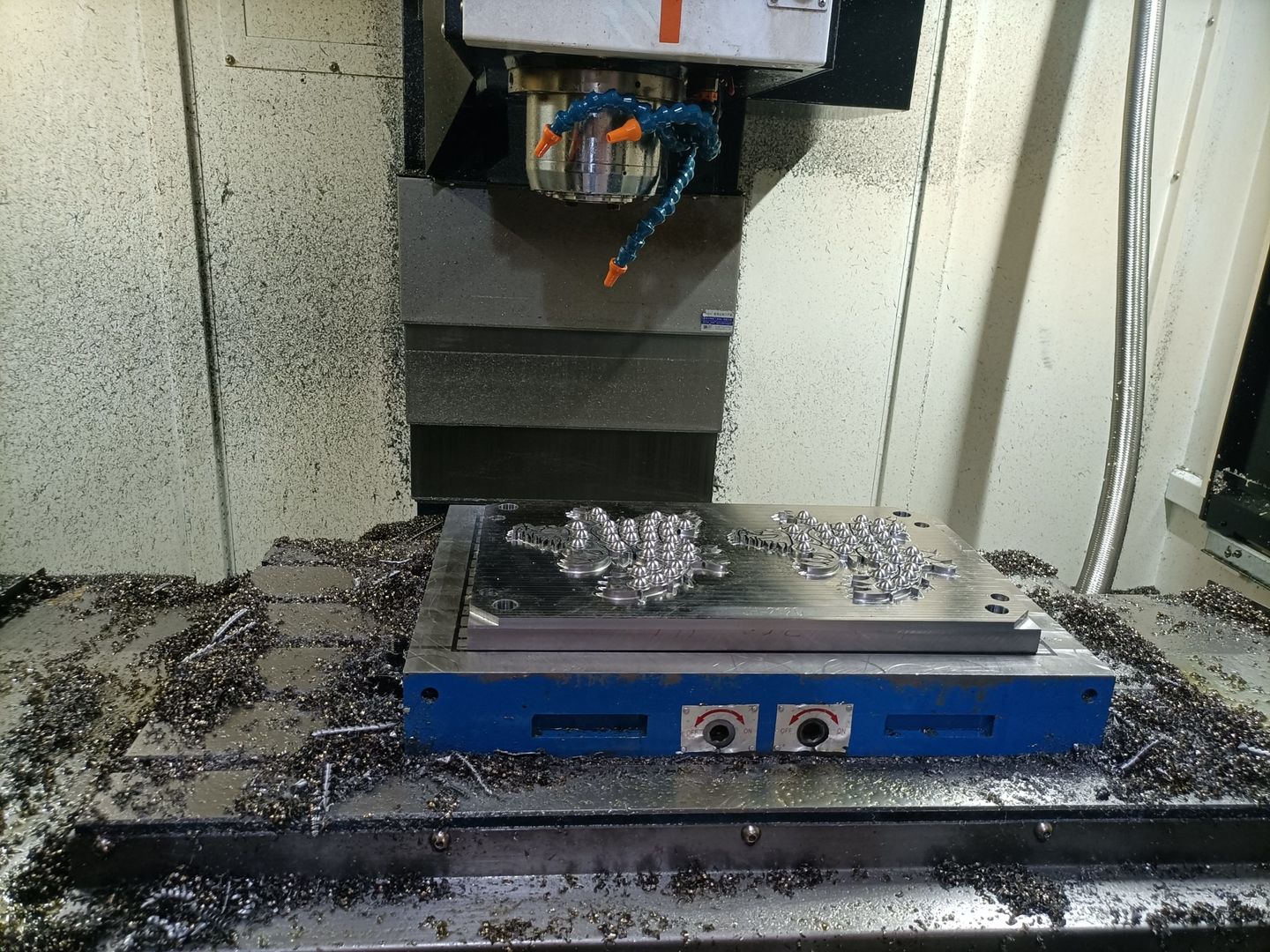

One of the main factors that can affect the mold cost of silicone products is the complexity of the design. More intricate designs will require more complex molds, which can be more expensive to create. Simple designs, on the other hand, may only require two basic mold, resulting in lower costs. There are two layers of mold, three layers of mold, or even four layers of complex structures.

Mold Material

The type of molds material used can also impact the cost. A mold that is expected to produce a high volume of products over a long period of time may require more durable materials, resulting in a higher cost.

Mold Size:

Larger molds will generally require more material and take longer to create, resulting in higher costs. Smaller molds, on the other hand, may be less expensive and easier to create.

Production Process

The production process used to create the silicone products can also impact the mold cost. For example, if the product requires a liquid injection molding process, the mold may need to be designed and created differently than for compression molding, resulting in different costs.

By taking above factors into account, you can better estimate the cost of creating customized silicone products that meet your needs and budget. If you wanna get a specific quotation for your goods, please don’t hesitate to send us email. From ideas to items, OECO are on the way, be with you.

![]()